1

/

of

5

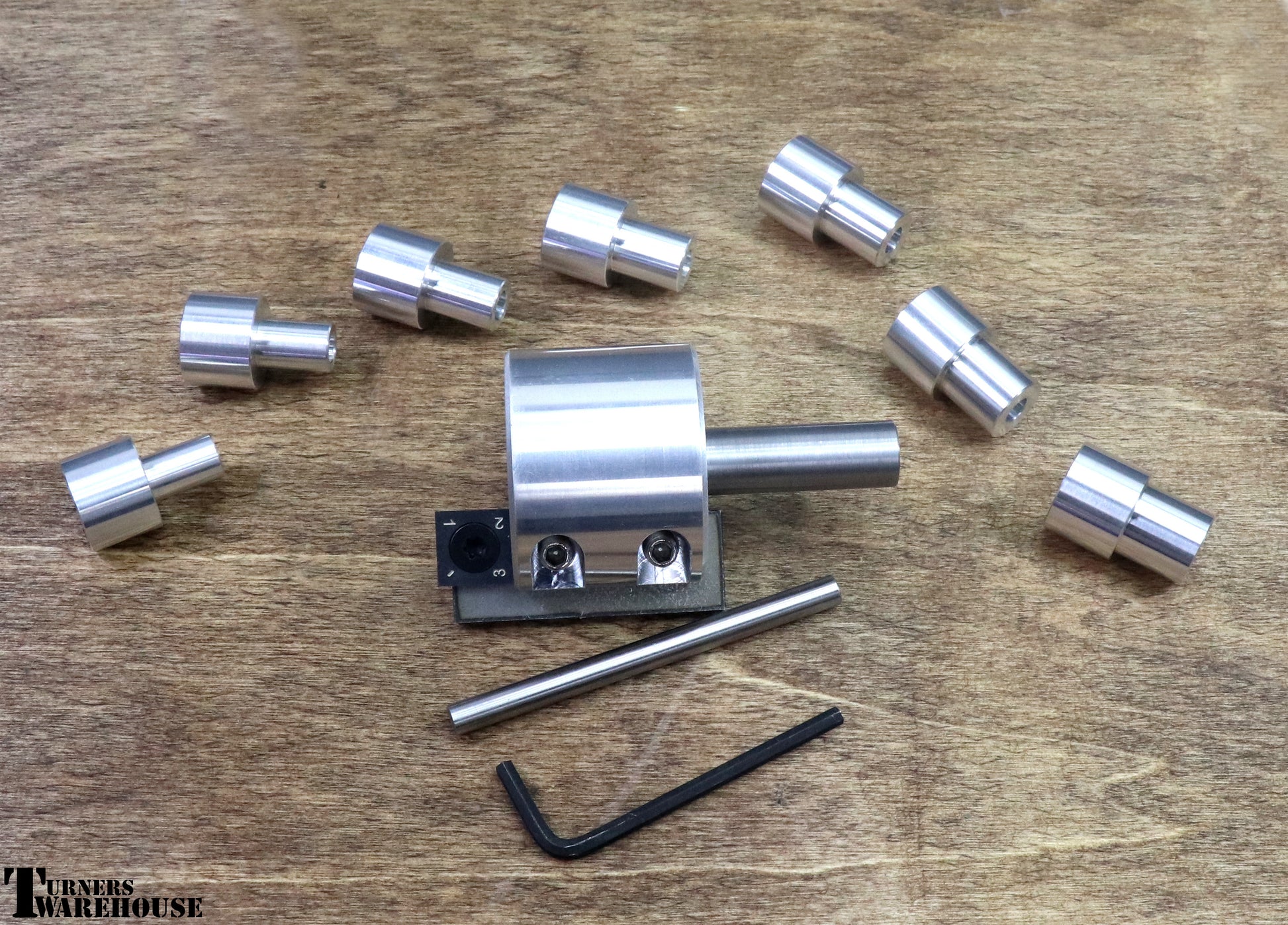

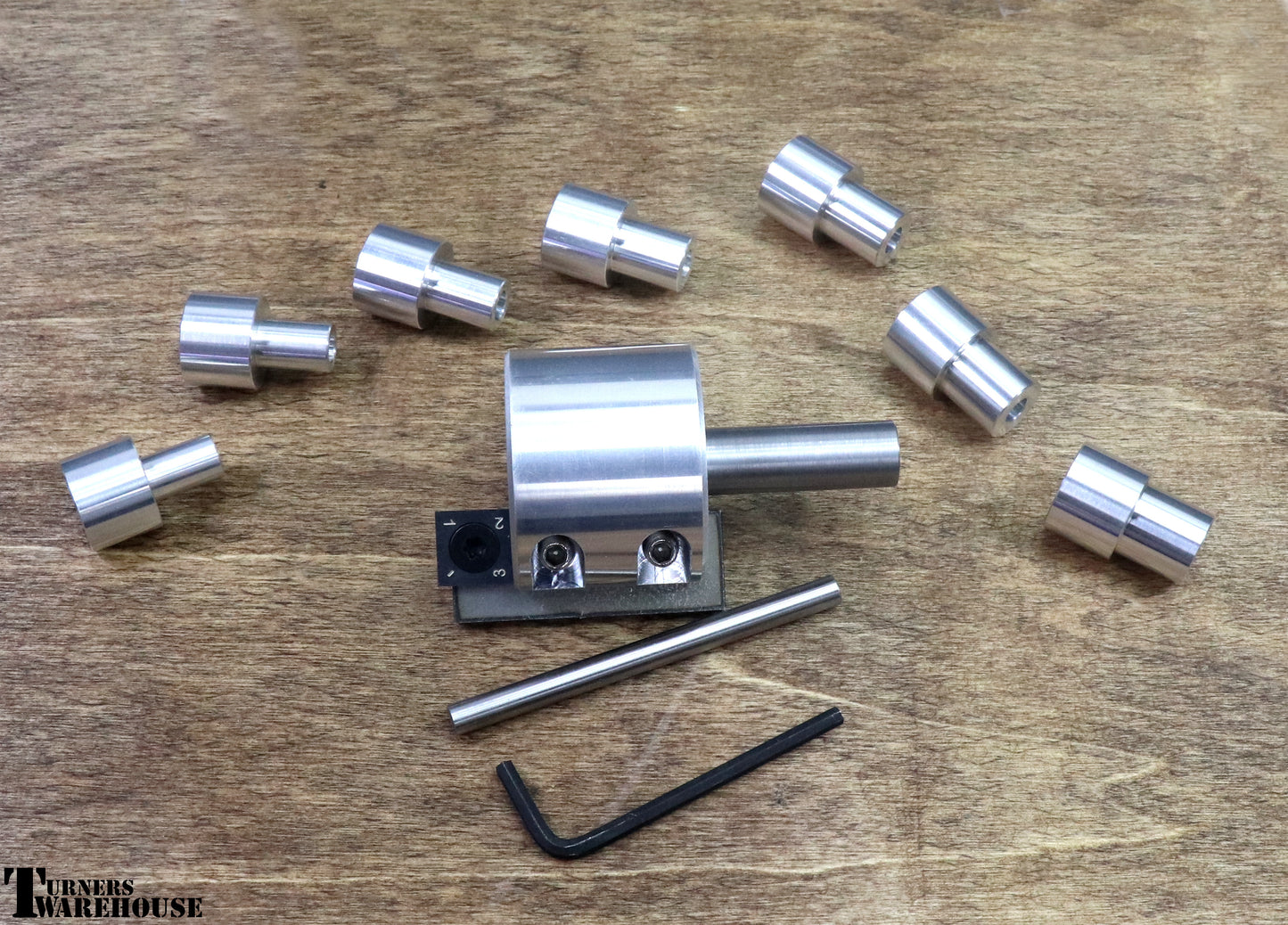

Hinze Tenon Cutter

Hinze Tenon Cutter

Product Specs

Product Specs

- Cutter Body

- Blade Holder with mounted carbide cutter

- M9 setup gauge

- M10 setup gauge

- M11 setup gauge

- M12 setup gauge

- M13 setup gauge

- M14 setup gauge

- M15 setup gauge

- Allen Wrench for blade adjustment

- Set Up Bushings Replacement set includes 1 of each setup gauge only

- Replacement Cutter head w/screw includes 1 screw and 1 carbide tip

Setup & Use

Setup & Use

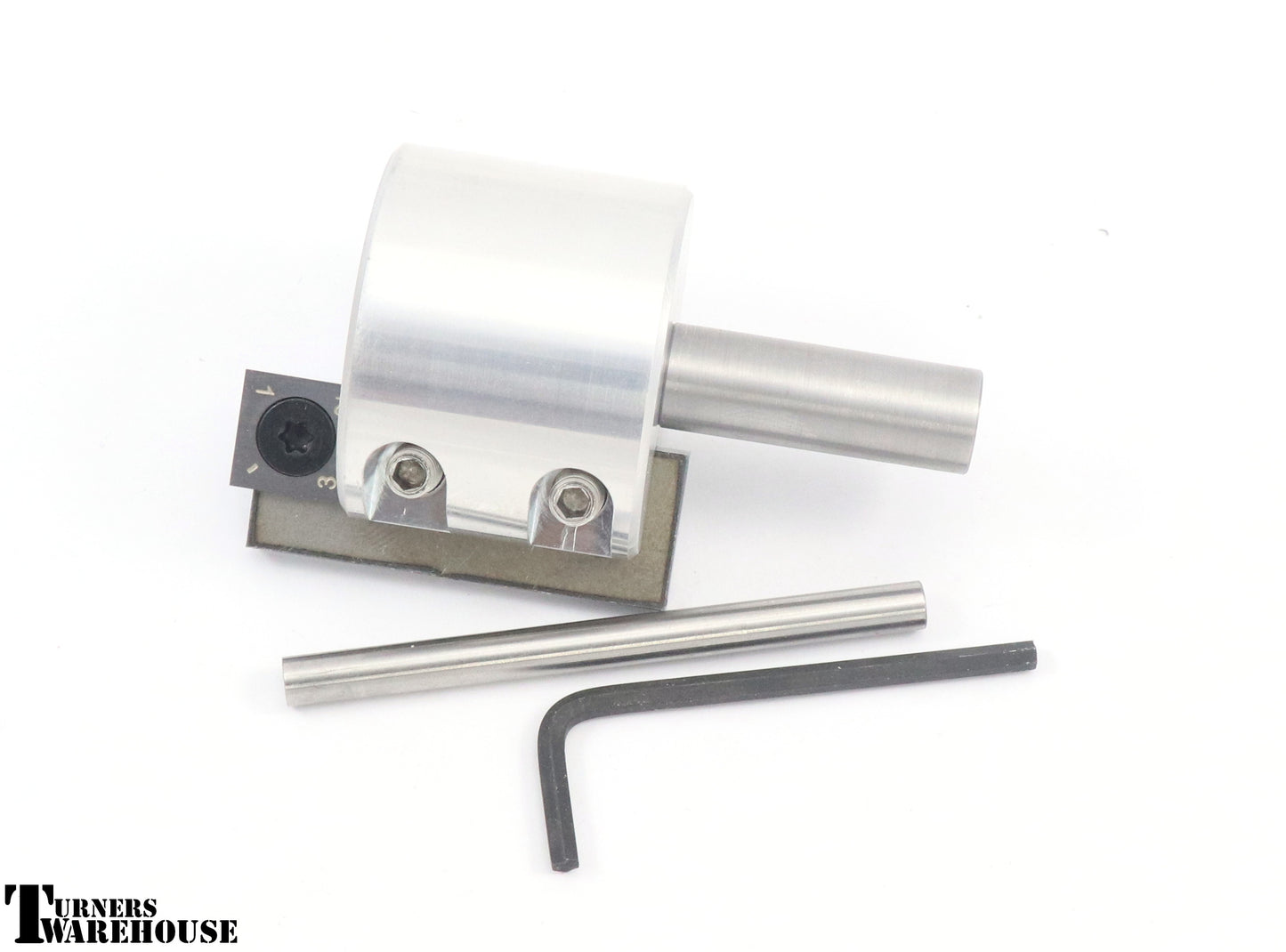

- Setup- Prior to use, you may want to place a drop of CA under the carbide blade. This will help keep it from spinning during a cut. This is optional.

- Use Ca or epoxy to glue in the shaft.

- Loosen the blade retaining cap head screws on the side of the body.

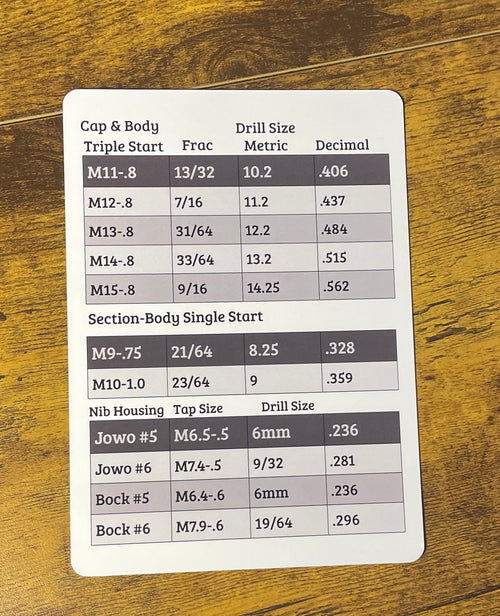

- Slide the desired setup gauge over the guide pin.

- Slide the blade holder/cutter into the slot, ensuring it rests easily on the small diameter of the gauge and is square to the shoulder.

- Do not press with downward force when setting the height, let the cutter rest on the gauge.

- Tighten the retaining cap head screws.

- Use- Drill a pilot hole in the material to receive the tenon using the letter 'A' drill bit.

- Mount the cutter in the Jacobs chuck. The work piece should spin around 1000 rpm (this seems to be the best speed). Gently extend the cutter's guide pin into the pilot hole (do not make contact with the blade yet).

- Hold the cutter body and the Jacobs chuck using one hand. When the cutter engages, you do not want the cutter to jump or twist (e.g. reduce the torque on the cutter by holding it securely).

- Cut the tenon to the desired length by using the tail stock hand wheel in one smooth consistent pass.

- Pull the cutter back and measure the tenon If tenon is over sized, repeat steps 3 through 7 using gentle downward pressure when holding the tenon cutter.

Pairs well with

Regular price

$169.99 USD

Regular price

Sale price

$169.99 USD

Unit price

/

per

Couldn't load pickup availability

Effortlessly create custom, clean and precise cuts for your bespoke pen making with the Hinze Tenon Cutter. Its sharp carbide tip and multiple size bushings ensure flawless results every time.

Share

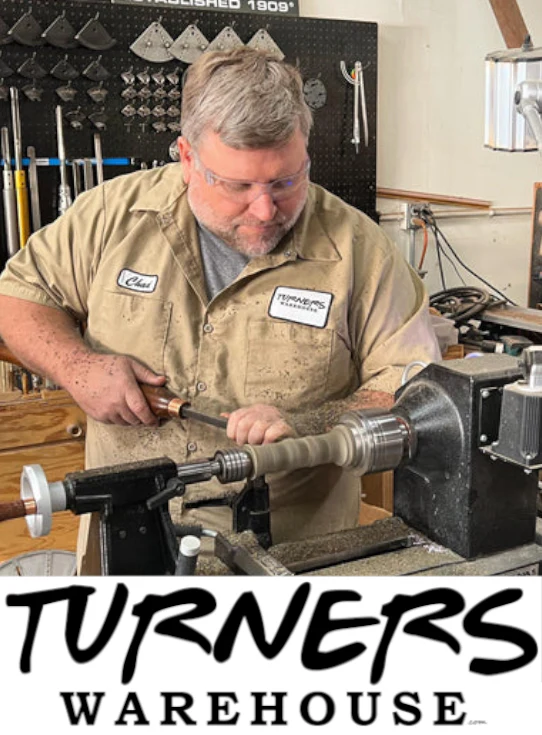

Turners Warehouse

Your home for everything turning, casting, & bladesmithing!

Check out our videos, live streams, classes & other educational content!